Asset Maintenance Checklists: Why Systematic Procedures Protect Millions in Asset Value

Your most valuable assets—art collections worth millions, multi-property estates, specialized equipment—are depreciating faster than they should. Not because of age or use, but because maintenance happens reactively instead of systematically. Asset maintenance checklists transform this reality by ensuring nothing critical gets missed while preserving institutional knowledge that typically walks out the door with departing staff.

In fact, the difference between assets that appreciate and those that lose value often comes down to one factor: whether maintenance follows documented procedures or depends on individual memory and judgment.

The Hidden Cost of Operational Silos

Unfortunately, asset management remains trapped in technological fragmentation for too many organizations. Spreadsheets become outdated the moment they’re created. Meanwhile, critical maintenance information gets buried in email threads. At the same time, team members maintain separate tracking systems, creating dangerous knowledge gaps when staff changes occur.

These disconnected approaches create significant challenges:

- Inconsistent maintenance execution across properties and assets

- Lack of historical data for performance analysis

- Difficulty tracking completion and compliance

- Inability to measure cost-effectiveness of maintenance programs

- Time wasted recreating procedures for similar assets

Moreover, the cost of these inefficiencies extends far beyond immediate operational challenges—it directly impacts the asset’s long-term value and ROI potential. For instance, when your estate manager leaves after ten years, how much maintenance knowledge disappears? Similarly, what vendor relationships, seasonal timing insights, and problem-solving approaches become inaccessible?

Research shows that fragmented systems and manual processes create inherent risks including missed maintenance requirements and inadequate documentation—problems that compound over time as institutional knowledge erodes. Four Family Office Trends to Watch in 2025

Standardized Asset Maintenance Checklists: Foundation for Value Preservation

In contrast, implementing standardized operating procedures (SOPs) through asset maintenance checklists transforms maintenance from a reactive scramble into a strategic approach that preserves and enhances value.

Benefits of Structured Maintenance Protocols

When properly implemented, maintenance SOPs deliver measurable benefits:

Consistent Execution First and foremost, no critical maintenance steps get missed. As a result, each asset receives the same quality of care regardless of which team member handles the work. For example, the HVAC servicing in your Aspen property follows the same rigor as the system in your Palm Beach residence.

Knowledge Preservation Additionally, institutional memory survives staff changes. Consequently, when your longtime property manager retires, the replacement inherits documented procedures instead of starting from scratch. Furthermore, vendor preferences, timing considerations, brand-specific requirements—all remain preserved.

Simplified Training Likewise, new team members become productive faster. Instead of shadowing senior staff for months, they follow documented estate management procedures that capture years of operational wisdom.

Risk Reduction Beyond efficiency, documented compliance with manufacturer recommendations protects warranty coverage and reduces liability. Therefore, when issues arise, you have proof that proper maintenance occurred on schedule.

Data-Driven Decisions In addition, comprehensive maintenance histories enable informed choices about repairs versus replacement, vendor performance, and budget optimization.

Cost Optimization Most importantly, preventing expensive emergency repairs through systematic maintenance reduces total ownership costs significantly. In practice, the $500 preventive service avoids the $15,000 emergency replacement.

However, the challenge has traditionally been creating and maintaining asset maintenance checklists in a way that’s accessible, adaptable, and actually used by maintenance teams.

How Technology Enables Systematic Asset Care

Fortunately, EstateSpace provides comprehensive solutions for physical asset oversight that address the fundamental challenges of siloed information and inconsistent execution.

Pre-Built Asset Maintenance Checklists

To start, the platform includes pre-built SOPs with every subscription, eliminating the need to create maintenance protocols from scratch. These templates cover common high-value assets—from climate control systems to pool equipment to art storage environments—and can be customized to specific needs and preferences.

AI-Generated Maintenance Procedures

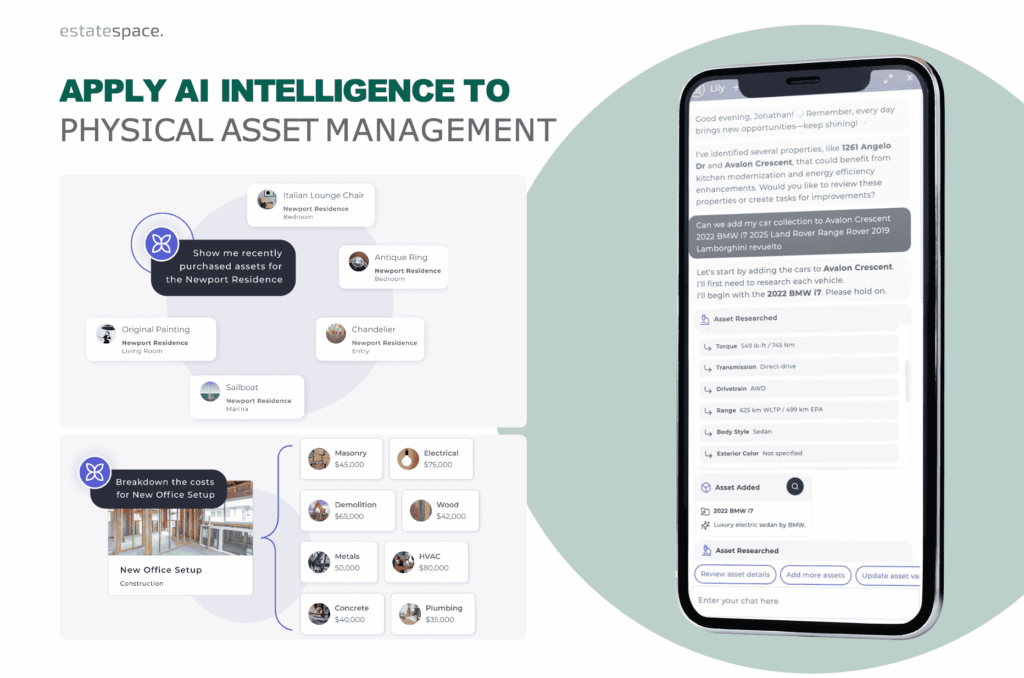

Even more impressive is the AI Assistant, Lily, which generates tailored asset maintenance checklists based on manufacturer recommendations, industry best practices, or specific brand requirements. As a result, this removes the burden of research and documentation from the asset management team while ensuring comprehensive coverage.

For instance, need procedures for a newly acquired yacht? Lily creates them based on the manufacturer’s specifications and marine industry standards. Similarly, installing a wine storage system? She generates appropriate climate monitoring and maintenance protocols automatically.

Integrating Checklists into Execution Workflows

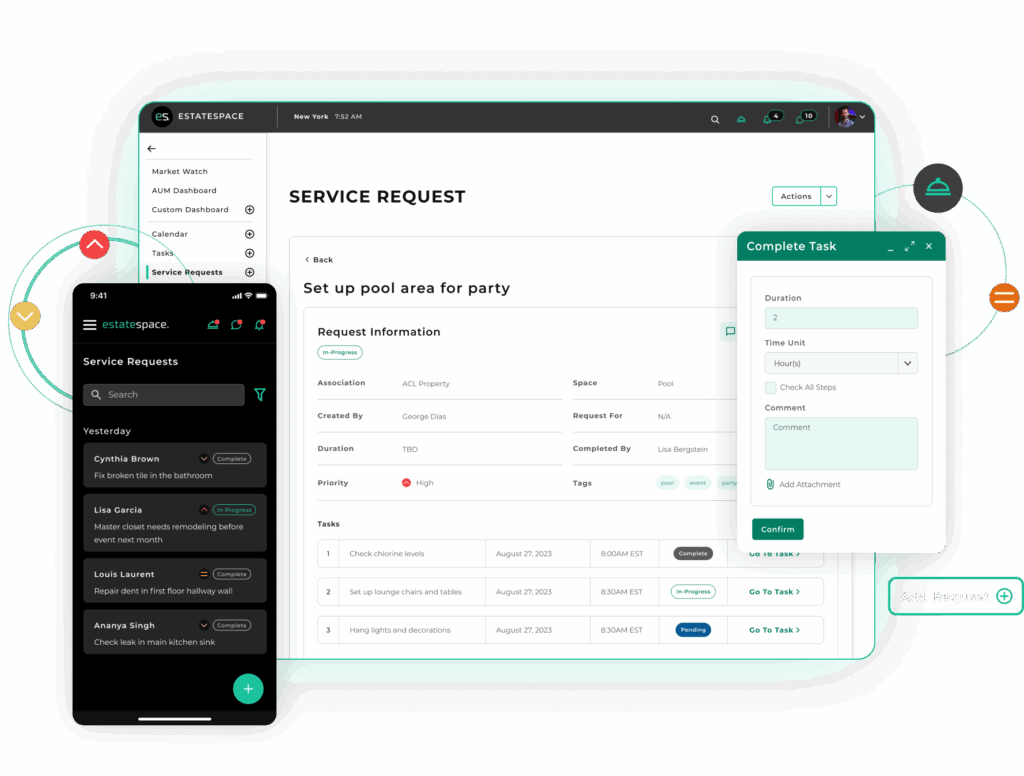

Nevertheless, what truly sets advanced asset management platforms apart is how they integrate procedures directly into execution. Specifically, asset maintenance checklists aren’t just stored documents—they become actionable tasks embedded directly into work assignments.

This integration ensures:

- Step-by-step guidance during maintenance activities

- Photo and documentation requirements at critical steps

- Verification of proper completion before tasks close

- Timestamps for compliance records and audit trails

- Historical documentation for future reference and analysis

For example, when your facilities team services the pool system, they follow the embedded checklist that prompts for chemical readings, equipment inspections, and filter maintenance—with photos required at each critical step. Subsequently, this documentation proves proper care occurred and creates data for predictive maintenance analytics.

Personalizing Care Protocols for Stakeholder Preferences

On the other hand, every asset owner has unique preferences and requirements. Therefore, the ability to tailor asset maintenance checklists to align with principal, family member, and guest preferences transforms standard upkeep into customized asset care.

Custom SOPs can accommodate:

- Specific cleaning products and methods for sensitive materials

- Temperature and humidity preferences for artwork and wine collections

- Detailed instructions for operating complex equipment when owners are present

- Specialized protocols for guest experiences

- Seasonal variations in maintenance requirements

Consequently, this personalization ensures that preventive care not only preserves value but enhances the ownership experience. For instance, the art collection maintenance checklist includes specific lighting preferences. Meanwhile, the guest suite preparation follows exact pillow arrangements and amenity preferences. Additionally, the pool maintenance schedule adjusts based on usage patterns and seasonal residence.

Moving from Reactive to Strategic Asset Maintenance

Ultimately, transforming maintenance programs from a cost center to a value driver requires shifting from reactive repairs to strategic preservation. In this context, standardized, accessible asset maintenance checklists are the foundation of this transformation.

Indeed, the most successful asset managers recognize that systematic upkeep directly impacts ROI through:

Preserved Value First, assets maintained according to manufacturer specifications retain value better than those receiving inconsistent care. As a result, that luxury vehicle properly serviced maintains higher resale value. Similarly, the estate with documented systematic maintenance commands premium pricing.

Reduced Emergency Expenses Second, preventive maintenance costs a fraction of emergency repairs. For example, the HVAC system that receives scheduled service doesn’t fail during extreme weather. Likewise, the roof properly maintained doesn’t develop leaks requiring interior restoration.

Extended Asset Lifespans Third, equipment and systems that receive proper care last significantly longer. Specifically, that $200,000 climate control system designed for 15-year lifespan reaches 20+ years with systematic maintenance. Meanwhile, the pool resurfacing scheduled for year 10 gets delayed to year 14.

Enhanced Operational Efficiency Finally, teams working from documented procedures complete tasks faster and more consistently. As a result, less time gets wasted figuring out what needs doing or how to do it. Instead, more time goes toward strategic initiatives that enhance service delivery.

Implementing Effective Maintenance Systems

To begin, starting this transformation requires understanding essential maintenance considerations for high-value assets. Whether you’re managing multiple estates, overseeing art collections, or coordinating complex equipment portfolios, documented procedures create consistency that protects value.

Key implementation steps:

- First, inventory critical assets requiring systematic maintenance

- Next, document current procedures where they exist

- Then, identify gaps where procedures are missing or inadequate

- After that, create or customize checklists for each asset category

- Subsequently, integrate into workflows so teams actually use them

- Finally, review and refine based on execution data

Importantly, technology platforms purpose-built for physical asset management accelerate this process by providing templates, AI assistance, and integrated execution tracking.

The ROI of Systematic Maintenance

Notably, the financial impact of implementing asset maintenance checklists shows up in multiple ways:

- 15-25% reduction in overall maintenance costs through prevention

- 30-40% fewer emergency repairs requiring premium pricing

- 20-35% longer asset lifespans reducing replacement frequency

- 40-60% less time spent on coordination and documentation

- Higher asset values at sale or transition due to documented care

For example, one family office managing three estates implemented systematic maintenance procedures and reduced annual costs from $625,000 to $487,000 while simultaneously improving asset conditions. Significantly, the savings came not from cutting maintenance, but from preventing failures and optimizing timing.

Start Protecting Your Asset Value

In conclusion, ready to transform your approach to preserving and optimizing your physical assets? The shift from reactive maintenance to strategic asset care begins with documented procedures that ensure consistent execution.

Schedule a consultation on maintenance systems for your portfolio →

Alternatively, explore how purpose-built estate management technology embeds asset maintenance checklists directly into execution workflows, ensuring procedures are followed consistently while capturing data that informs strategic decisions.

Related Resources: